Getting started with 3D printing

Why 3D printing?

3D printing allows you to manufacture plastic objects at home/work without actually making them yourself! Once you have set the printer up, you press print and a few hours later, your objects are in your hands. It’s perfect for prototyping and testing toys and games.

Getting a 3D printer to reliably print any object will take time to learn though because each printer, material and design is different, and all have their own quirks. There are multiple ways to print 3D models and over time, you’ll learn the best method for each object you want to print.

Choosing a printer

What type of toys or games do you want to 3D print? This is the first question to ask yourself when you’re looking to get a 3D printer.

If you’re printing objects that are static (i.e., no moving parts) and have lots of detail, it’s often best to get a resin 3D printer. These use a vat of liquid resin to build up a model. Resin printers allow you to print in very high detail (also called resolution) compared to other types of printers.

The liquid resin does have downsides though, including warping for thin/flat parts and it can wear away quickly with friction. ‘Post-processing’ resin 3D prints can be time consuming after they have finished printing, with vats of cleaning fluid and UV light curing.

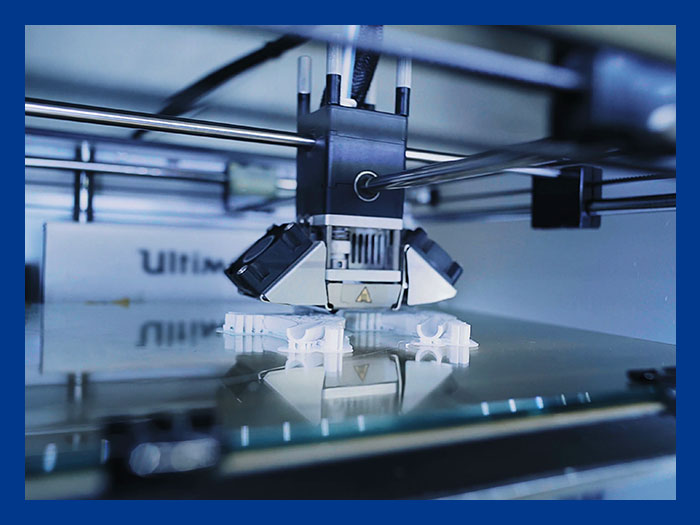

If you’re printing objects that have moving parts and need to withstand repeated use, it’s best to get a filament 3D printer. These are less detailed than resin printers but the materials they print with can withstand repeated uses (such as ABS or Polycarbonate). It’s also a lot easier to ‘post-process’ the 3D printed object once it has finished printing compared to resin – you simply remove the 3D printed supports and that’s it.

More advanced 3D printers use technology such as sintering but we’re going to focus on consumer-level 3D printers. Each technology has its advantages and disadvantages, but FDM and Resin printing can accomplish 95% of toy and game prototyping needs. For extremely high precision and strong forces, CNC machines are usually better to use.

Setting it up

The first thing to do is to make sure you’ve got an area to use your printer. I highly recommend a well-ventilated room just for the printer(s) – I’ve been using 3D printers for a long time and the fumes they give off when printing are not good!

If you’re using a resin printer, you’ll need the printer itself, 3D printing resin (available with different properties), isopropyl alcohol (for cleaning the print after printing) and a UV light box (for curing the prints after cleaning). Once you have these, you can go through the calibration process which mainly involves making sure the printer is on a level surface. You then either pour the resin into the resin tank yourself or it gets fed in automatically with more advanced resin printers (e.g. Formlabs printers). Then you’re ready to go!

For filament printers (also called FDM printers), you’ll need the printer itself and a roll of 3D printing plastic filament (such as PLA, PETG or ABS). Some plastic filaments like to warp when printing – which is a problem! – so getting an enclosure to put around your 3D printer is usually a good idea as it keeps the heat in, lowering the chances of warping. Once you’ve fed the filament into the ‘print head’ (it’s like feeding a glue stick into a glue gun), you can run through the printer calibration, which it can usually do itself. Now you’re ready!

What can I print?

Once you’ve got the 3D printer all set up, you’re ready to find a nice 3D model to print!

3D printing websites such as Thingiverse give you 3D models to download and 3D print. You could use those 3D models to print prototype game pieces or toy parts while you’re developing and testing. There’s a big selection of files but you might find it hard to find exactly what you’re looking for.

When you’re licensing to toy and game companies, it’s usually best practise to create everything from scratch unless they’re just placeholder designs. Other websites such as Cults3D.com and cgtrader.com also offer 3D models to buy. This way, you can 3D print without learning how to 3D model, although it’s harder to customise the models or create something unique without learning that skill.

If you learn how to 3D model, you can create your own 3D models in programs such as Fusion360 or Solidworks. You then export them as .STL files (the most common format) ready for 3D printing.

First prints

Now you’ve got a 3D printer and 3D file, you’re nearly ready to 3D print!

Before starting the 3D print process with the 3D printer, you’ll need to configure the settings in something called a ‘Slicer’ program on your computer.

3D prints are made using layers of a material (both resin and filament 3D printers) and that’s why the programs are called ‘Slicers’ – they take your 3D file and digitally ‘slice’ it into layers. By doing this, it allows the printer to understand how to 3D print your 3D file.

Besides slicing the 3D file, you’ll usually need to add ‘supports’ to the 3D file. These supports hold up the 3D model as it’s being printed so it doesn’t collapse on itself when it’s printing.

Once you’ve done that, you can either send the new 3D file to the 3D printer over Wi-Fi or manually transfer it using a memory card. Then you press ‘Print’ and off it goes – a few minutes or hours later and you’ve got your brand-new toy or game part!

If you want to see how toys and games are made, follow along and create one from idea to prototype, the Toy and Game School will show you how! Visit www.toyandgameschool.com to learn more and sign up during Early Access to get instant early access to each level as it’s released.

Early Access to ‘Level 1 – The Toy and Game Industry’ is available now!

—

To stay in the loop with the latest news, interviews and features from the world of toy and game design, sign up to our weekly newsletter here